Process Fired Heaters

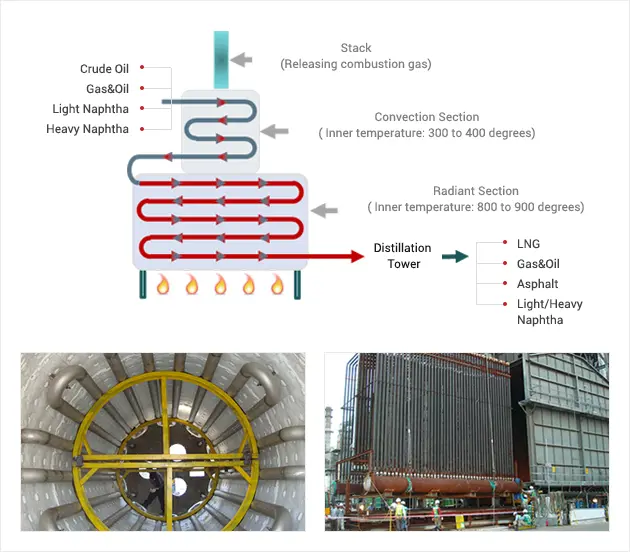

Structure of Fired Heaters

Fired Heaters

Fired Heaters in Oil & Petrochemical Plants.

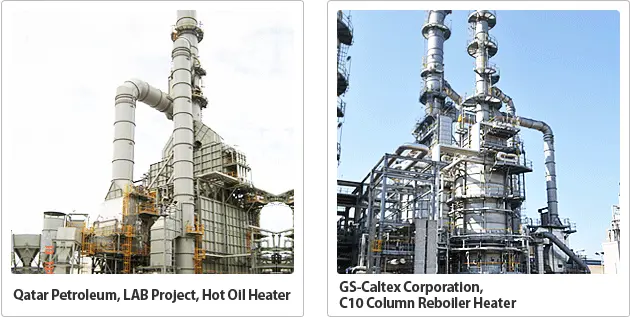

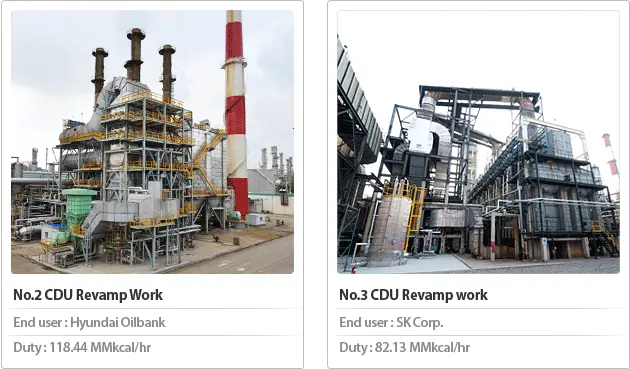

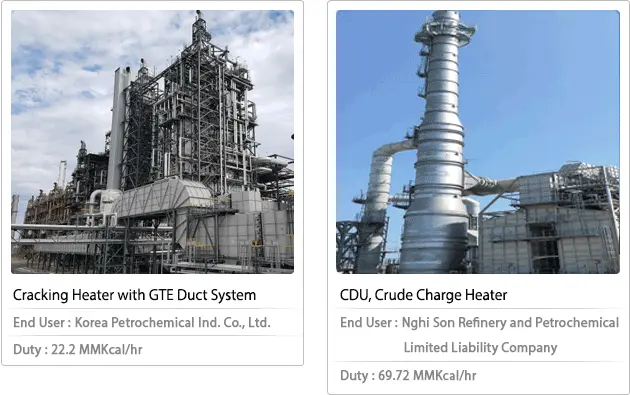

Plants consist of Oil Refining, Petrochemical, Ethylene, Gas&Oil, LNG and so on, and each plant needs various fired Heaters specialized in. Several Fired Heaters are installed in a plant. Since Fired Heaters have a major effect on plants safety as an equipment related with fire, various experience and performance are the most important evaluation elements of clients in selecting Fired Heater supplier.

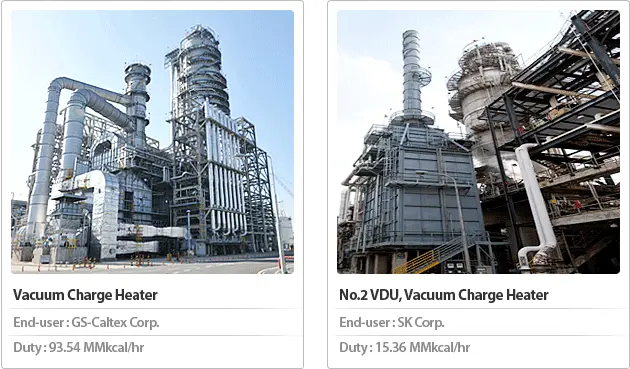

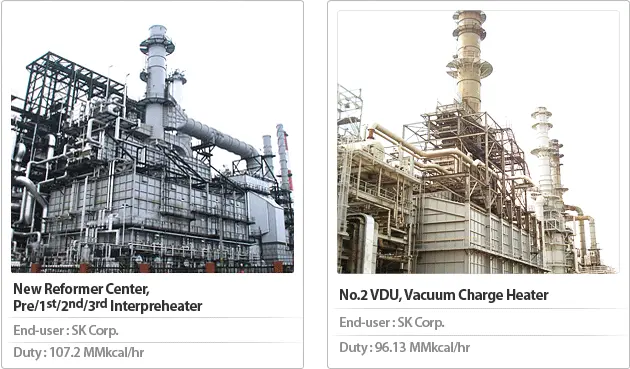

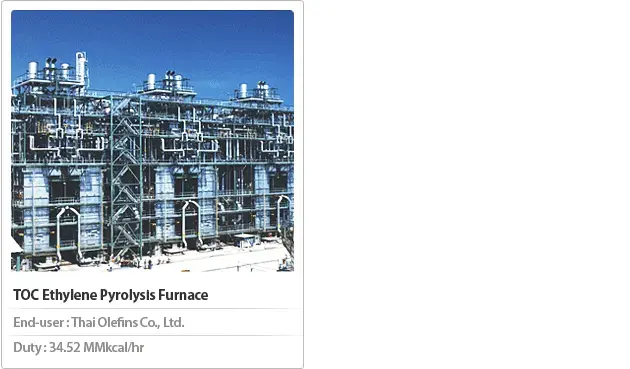

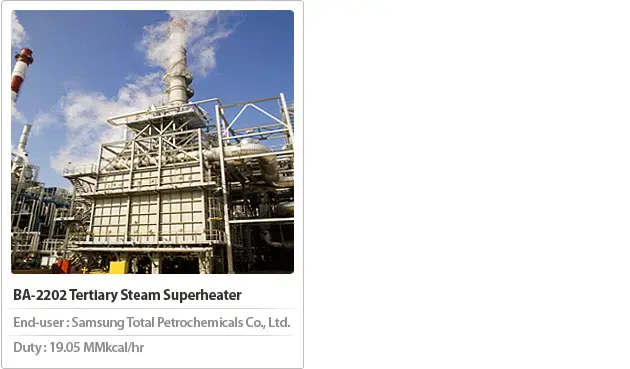

JNK has performed various projects such as Crude Distillation Unit, Vacuum Distillation Unit, Steam Reformers successfully in the above plants and able to provide process design (thermal & mechanical design) of fired heaters to clients.

Process Fired Heaters

- Crude Distillation Unit (CDU) Heaters

- Vacuum Distillation Unit (VDU) Heaters

- UOP CCR Platforming/AXENS Aromizing Heaters

- Pyrolysis Furnaces (Naphtha Cracking Furnaces)

- Steam Reformers

- Steam Superheater

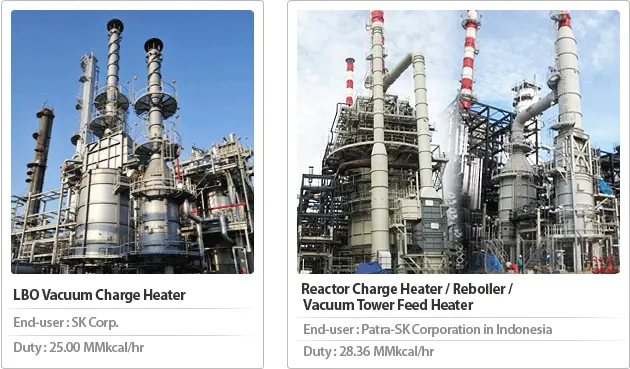

- LBO (Lube Base Oil) Heaters

- OCU (Olefins Conversion Unit) Heaters

- Other Heaters

Crude Distillation Unit (CDU) Heaters

Vacuum Distillation Unit (VDU) Heaters

UOP CCR Platforming/AXENS Aromizing Heaters

Pyrolysis Furnaces (Naphtha Cracking Furnaces)

Steam Reformers

Steam Superheater

LBO (Lube Base Oil) Heaters

OCU (Olefins Conversion Unit) Heaters

Other Heaters